Automated Amine Clean-Up Systems for World-Scale Sour Gas Treatment Plants

High efficient Solid/Liquid Separation

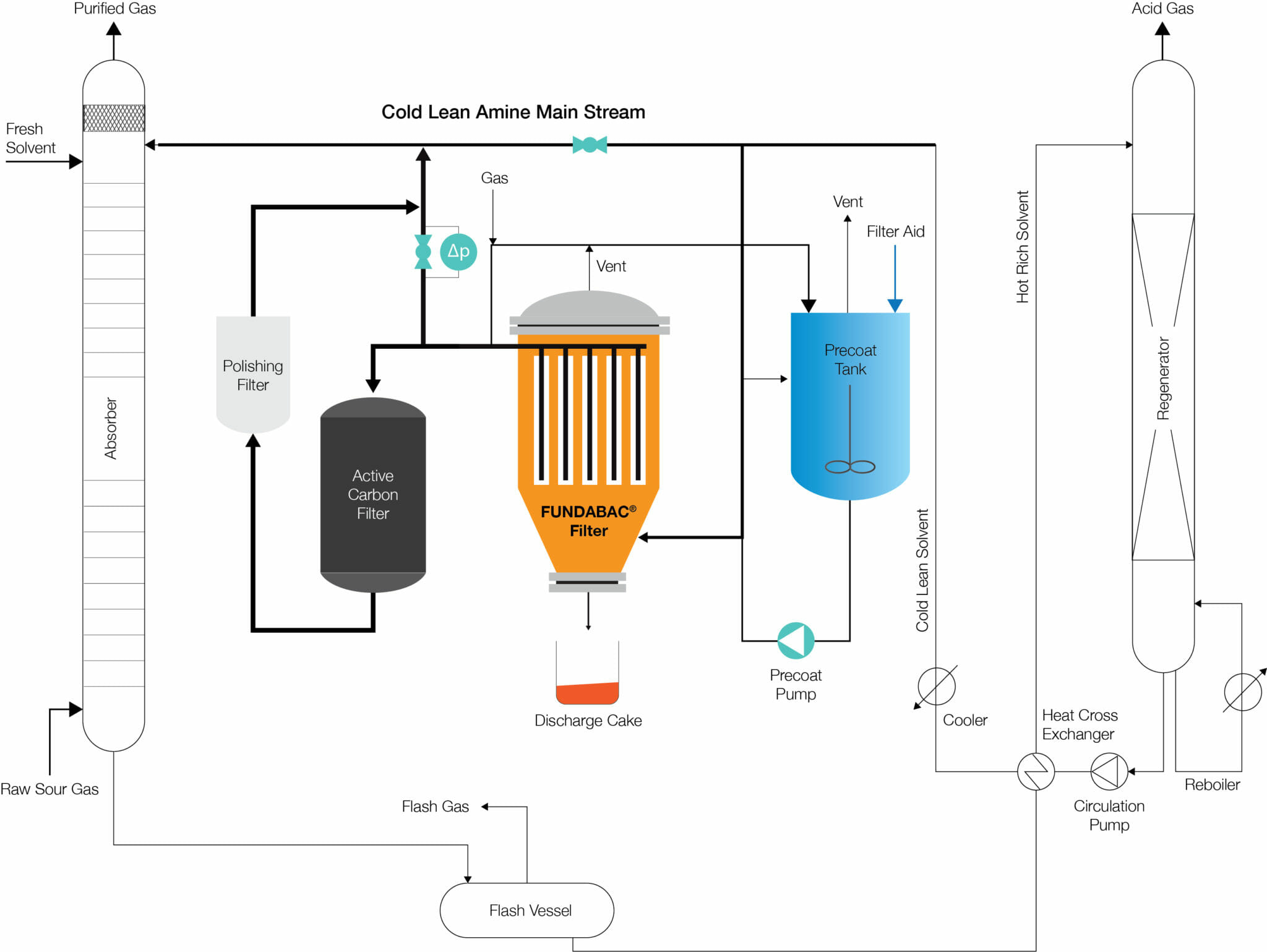

The effective and efficient removal of H2S, CO2 and other contaminants from gas streams is a key issue in the Oil & Gas industry. This is normally achieved by wet scrubbing using a proprietary alkanol amine (for example, MEA. MDEA. DEA, OASE) to “sweeten” the sour gas.

The amine solvent is regenerated by passing the it through a regeneration column. However, the amine solvent becomes contaminated with insoluble solids, which cause corrosion in the scrubber and pipework and, more critically, foaming and fouling in the regeneration column.

In order to eliminate these issues, filters are often fitted to the lean amine stream to remove the insoluble solid contaminants. It is typical to fit these to a 10% or 20% slip stream.

Whilst various types of replaceable cartridge type filters have been used on the lean amine slip streams, these have proven to be maintenance and OPEX intensive. The DrM FUNDABAC® has shown to provide a far superior solution, due to the ability to automatically discharge the collected solids as a dry cake and because of the very low maintenance requirements and OPEX associated with this special design of filter from DrM.

To date more that 120 DrM FUNDABAC® filtration plants have been supplied for this gas sweetening process, on a range of medium and large plant sizes. If you would like further more detailed information on the FUNDABAC® technology, amine treatment process, capabilities and economics, please contact us at our of our offices.