CMMF – Combined Micropollutant and Microplastic Filtration as innovative quaternary municipal wastewater treatment

PAK precoat candle filtration

Emerging contaminants in the environment are an ongoing national and global water challenge. Two groups of contaminants are of higher concern in waste and drinking water management: micropollutants (MP) and microplastics (MPlas).

Municipal wastewater treatment plants are considered as point sources. Different countries already regulate their discharge pathways via wastewater treatment plants with, for example, a target value of 80% reduction.

In the CMMF project, we have developed a technology that successfully removes microplastics and micropollutants, and contributes to sustainable ecology through its high effluent quality. The technology is based on the DrM precoat filtration, in which a vertical installed textile (filter cloth) is precoated with different functional layers (filter cake).

CONTIBAC® RX pilot unit.

A pilot plant with 1m2 filter cloth area was installed on a municipal wastewater treatment plant (WWTP Rancate, 50’000 PE), treating secondary clarifier effluent to validate the laboratory findings and operate the system under real conditions.

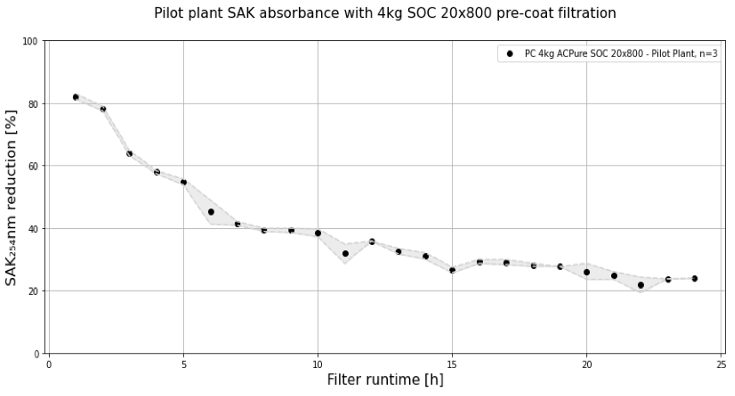

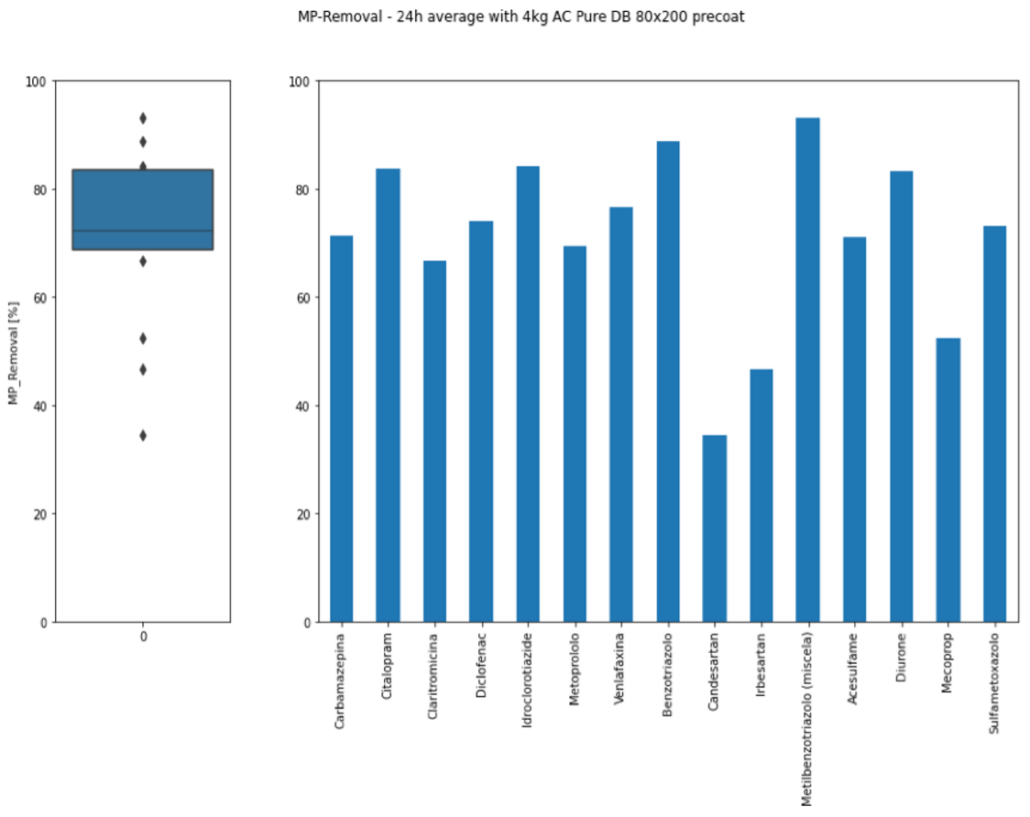

The micropollutant elimination performance was correlated with absorbance measurements at 254 nm (Spectral absorption coefficient – SAK) and regular HPLC-MS/MS analytics. The targeted 80% removal efficiency was reached with 2 and 4 kg/m2 powdered activated carbon precoat.

Pilot plant SAK reduction over a filter runtime of 24h.

Quantitative reduction of fifteen analyzed micropollutants from a 24h composite sample.

The precoat candle filter can operate directly and does not require any upstream reaction or sedimentation tanks. After an operating time of up to 24 h the filter is exhausted and needs to be backwashed and recoated. The partially loaded carbon cake can be used again for a second precoat. This shall be done to reduce the activated carbon consumption.

Today, the carbon consumption amounts to approx. 2.8 – 3.2 mgPAC/mgDOC treated wastewater.

Once operated with a carbon cake, the total suspended solid (TSS) retention of the filter is guaranteeing low values of < 1 mg/L TSS. Hence, the PAK-retention can be assumed higher than 99%.

Close-up of the CONTIBAC® RX filter media.

Microplastics retention down to 50 µm particles is investigated in the project. The total solid retention indicates a complete retention is reached for particles bigger 100 µm. The characterization of the treatment plant effluent and pilot plant effluent is ongoing.

Conclusion

- The CMMF project idea of operating a PAK precoated candle filter as quaternary treatment step is feasible and demonstrated treating secondary clarifier effluent of the wastewater treatment plant of the WWTP Rancate (TI). Compared to today’s state-of-the-art applications, the new process convinces with:MP reduction to comply with water directives

- Effective solid particle retention (TSS concentration of < 1 mg/L in the effluent)

- Direct precoat filtration, no upstream reaction Tank required

- No or negligible activated carbon loss

- Carbon recoating ensures good PAC utilization

- Increased COD retention

- Modular setup allows for high process flexibility

- Low space requirements

- Fast start-up

- Resistant to solid load and flow fluctuations

- Process can be fully automatized

These pilot tests and the evaluation of the results, were carried out from November 2021 – December 2022, by:

Scuola universitaria professionale della Svizzera italiana, CH-6850 Mendrisio, Dipartimento ambiente costruzioni e design, Istituto Microbiologia – BET.

Project Partners

Dolder AG, CSD Ingenieure, SUPSI, CDAM and DrM, Dr. Mueller AG.