DrM develops the CONTIBAC® XF SIKA Crossflow filter

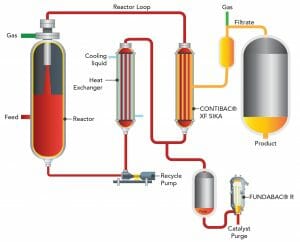

DrM develops the CONTIBAC® XF SIKA Crossflow filter for continuous catalyst recycle from slurry hydrogenation reactors. The ideal combination with FUNDABAC® R for catalyst purge removal.

Background

Heterogeneous hydrogenation is widely applied in many fine chemical, pharmaceutical, and food sectors and is one of many process steps in chemical synthesis. Often, such processes are batch oriented where each batch is treated individually. The FUNDABAC® candle filter has traditionally played an important role in the recovery of noble metal or Ra-Ni catalyst as it accomplishes complete batch integrity. For the recovery of catalyst in continuous operations, the simple design of the CONTIBAC® XF SIKA crossflow filter allows easy integration especially in loop-type hydrogenation reactors.

Design Features and Benefits

DrM has teamed up with GKN Sinter Metals Filters GmbH, a leader in the field of sintered metal, to offer the CONTIBAC® XF SIKA crossflow filter. This unit comprises a set of sintered metal tubes in a tube sheet arrangement where the liquid passes each tube wall at a velocity that prevents formation of a particle layer. A portion of the liquid passes through the porous sintered metal tubes and leaves it free of solids.

- Fine pore size

- Excellent filtrate quality

- Simple installation

- Easy process control

- Long service life

- Robust seamless elements