Maritime Off Gas Scrubbing

Background

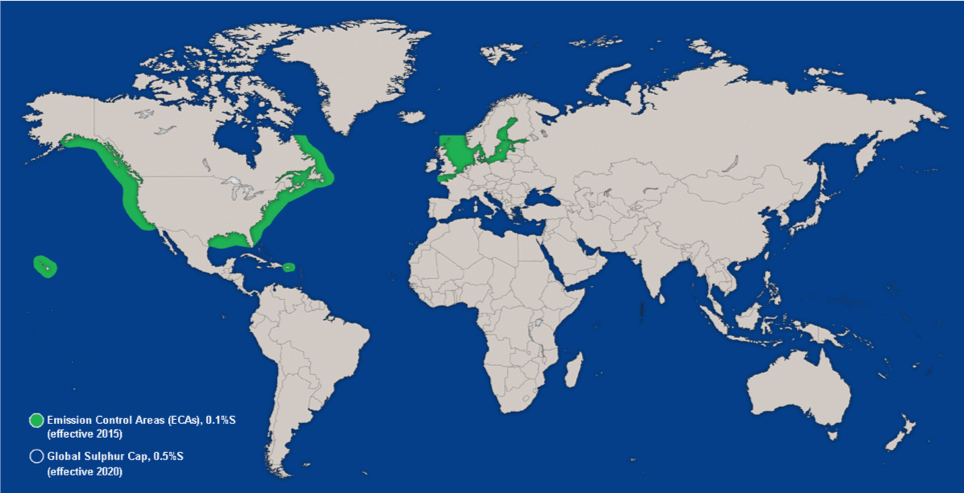

The maritime industry is facing great changes: Starting 1st of January 2020, vessels without exhaust-gas scrubbers will only be allowed to use fuel with a maximum sulphur content of 0.5%, while an even stricter 0.1% limit applies in Emission Control Areas (ECAs). The current industry standard is fuels with a sulphur cap of 3.5%. Only ships equipped with exhaust-gas scrubbers can continue to use cheaper high-sulphur fuel oil, HSFO. The so-called IMO2020 regulation is the first in a series of International Maritime Organization (IMO) measures to reduce marine pollution.

Global Sulphur Cap and Emission Control Areas (ECA’s) around the Globe

Maritime Exhaust Gas Scrubbing & Water Filtration

The legislation refers to fuel sulphur levels but allows the shipping industry to use abatement technologies, provided that the technology reduces the emission of SOx into the atmosphere at the same or lower levels. In this sense scrubbers are recognized an efficient technology to reduce sulphur and particulate emission.

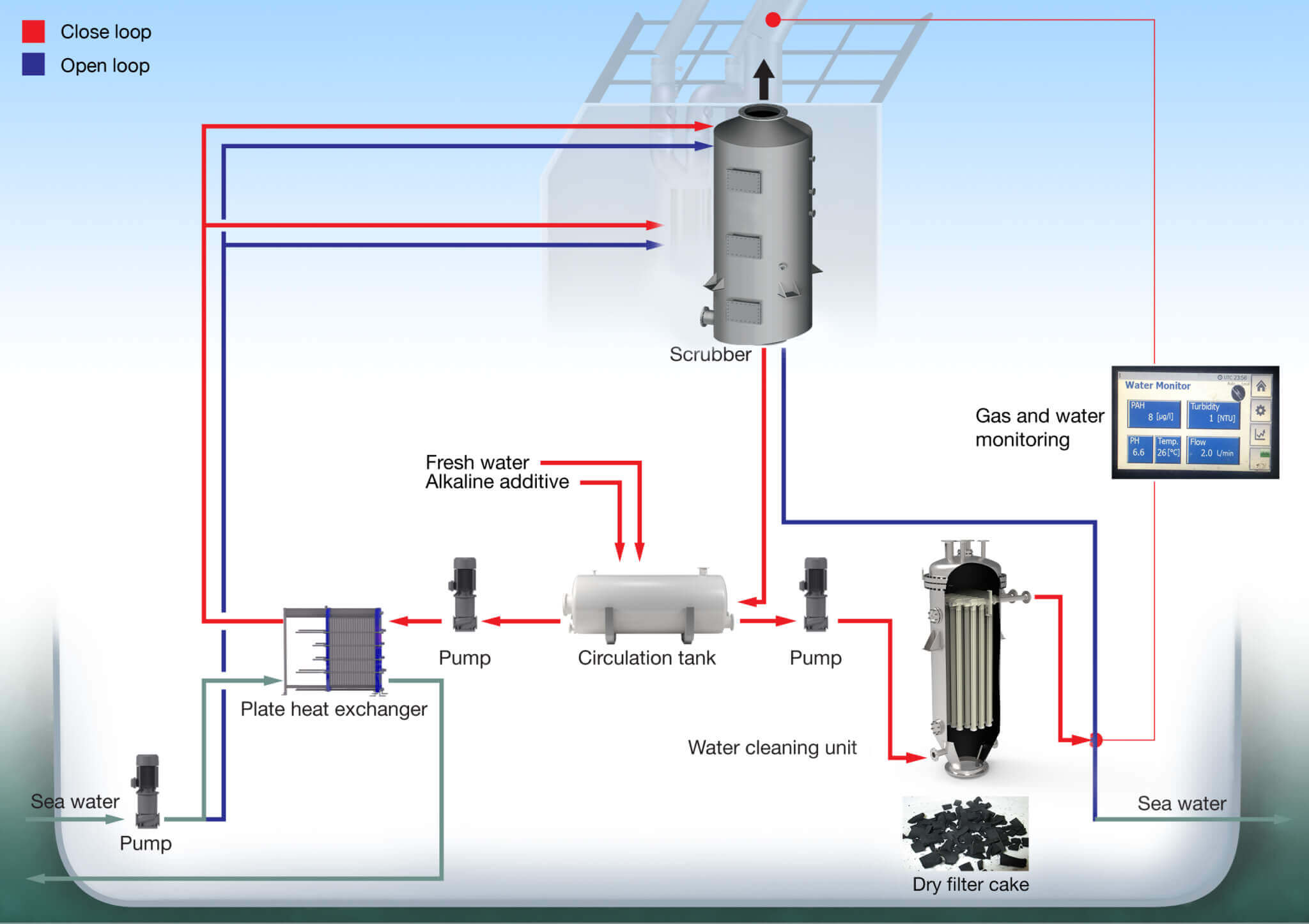

Scrubbers are configured in different ways, as open loop, closed loop or hybrid systems. Nowadays most ship owners select a hybrid system, which balances economy with operating flexibility. In a hybrid scrubber arrangement, both open-loop and closed-loop modes (blue and, respectively, red line in the schematic below) are readily available. Open-loop operation reduces costs whenever possible, but a switch to closed-loop operation can be made whenever local water discharge regulations demand it.

Closed loop or hybrid systems require an efficient water cleaning unit, as the recycled water always needs to be kept within a certain quality in order to have a proper sulphur removal from the exhaust gases and avoid any precipitation and consequent fouling anywhere in the loop. Emitting off-gas not being compliant with the environmental regulations is severely fined by local authorities.

Whereas a variety of scrubber designs are available on the market, thus allowing to select among a number possibilities for the off-gas cleaning itself, the proper treatment of the scrubbing liquid is a challenge that cannot be regarded as properly addressed so far. Currently available filtration technologies have certain disadvantages and limitations, such as :

- discharge of wet sludges that cause high disposal cost or require further on-shore treatment

- complicate multi-stage treatment systems

- excessive use of chemicals, filter aids or additives

Pilot Testing on Stena Line Vessels

DrM already holds an extensive experience in filtration of scrubbing liquid from flue gas treatment system, with 170+ units already in operation on this same application worldwide, half of which deployed exactly for SOx absorption and soot removal.

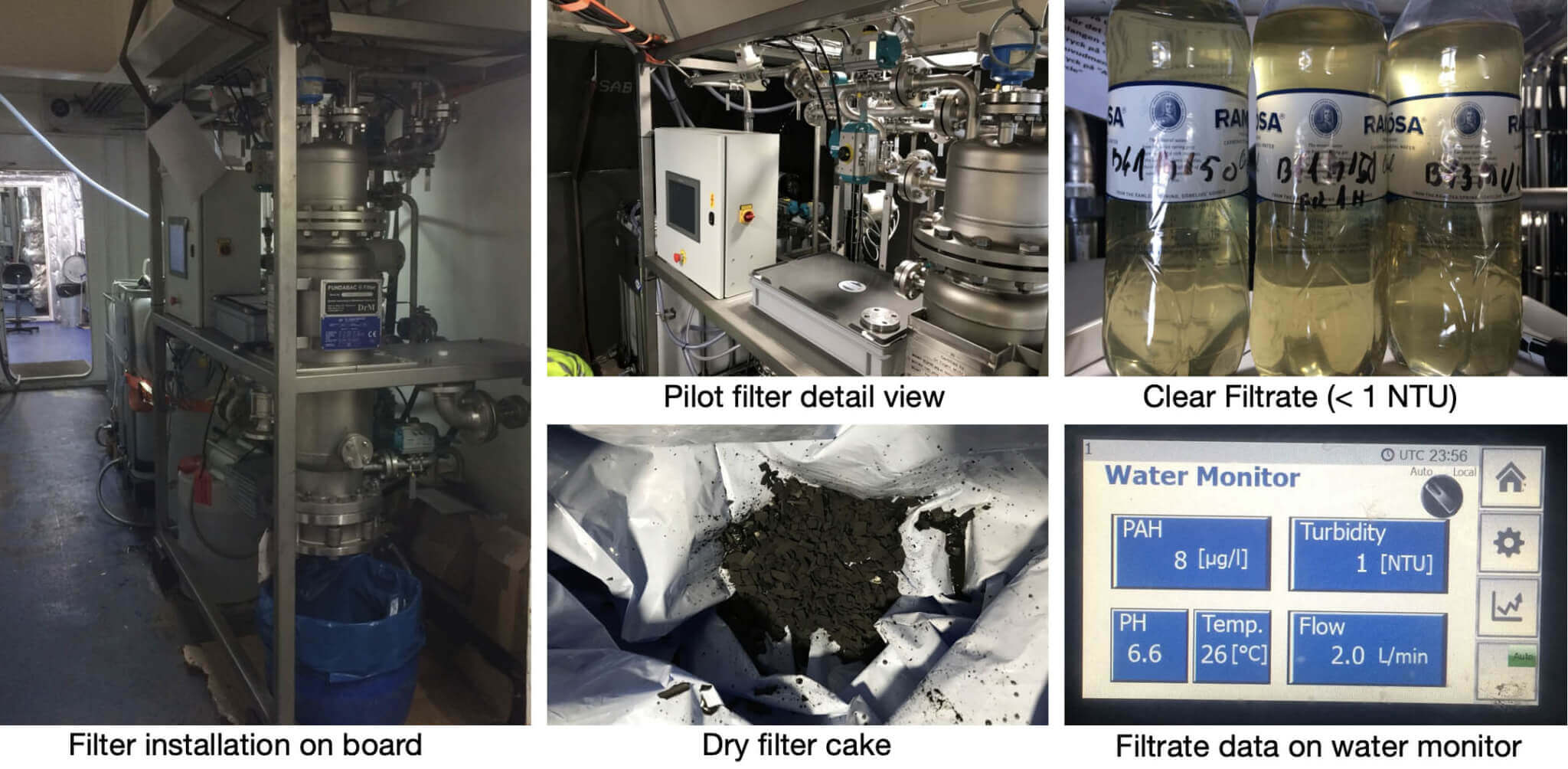

On the basis of such a comprehensive background, DrM teamed up with a shipping company for on-board filtration testing. Objective of the campaign was to test a novel, single stage filtration system under realistic conditions.

Following lab testing at DrM’s facility in Männedorf a DrM FUNDABAC® pilot filter system was installed on two different vessels for several months, Stena Vinga (Sept.- Oct. 2019) and Stena Scandinavica (Dec. 2019- March 2020).

Results and Conclusion

Pilot tests proved the performance and advantages of the FUNDABAC® Filter System:

- Single stage, direct filtration system

- Discharge of a dry filter cake, alternatively slurry discharge possible

- Clear filtrate with turbidity < 1 NTU

- No use of chemicals, flocculants, filter aids or “magic” additives

- Closed system, automatic operation, low operator intervention

- No rotation or moving parts, no drives or mechanical seals

- Simple, reliable and efficient

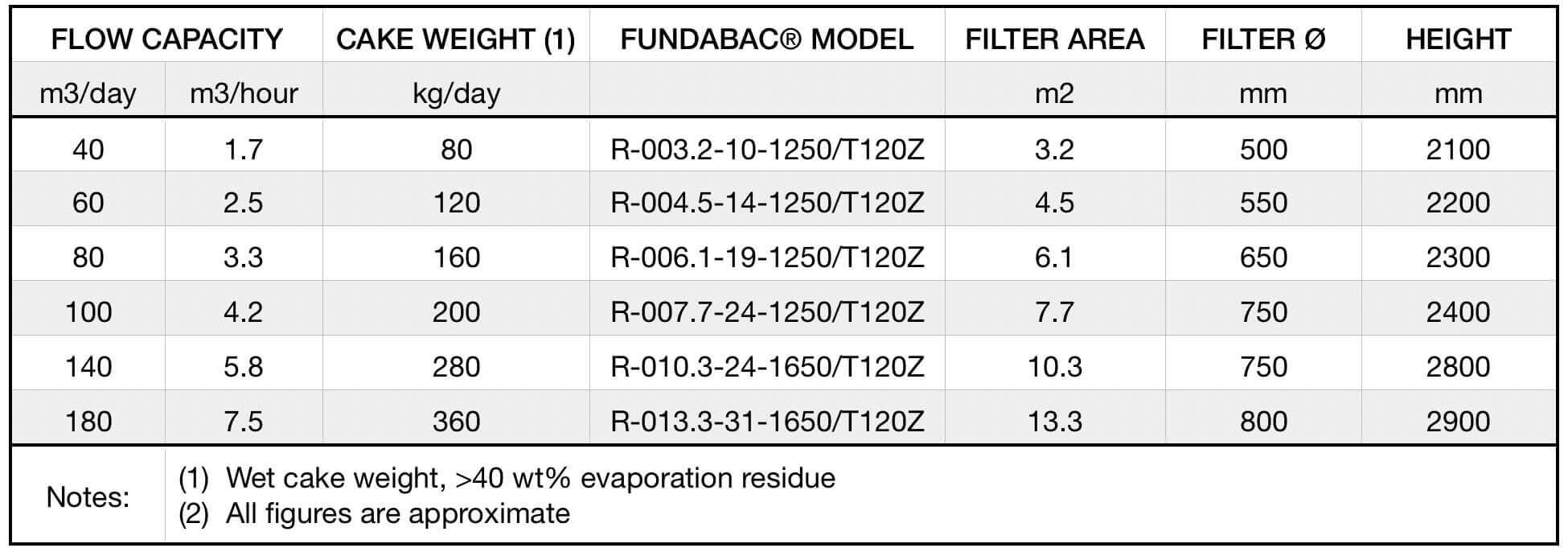

Based on the experimental results obtained during the pilot scale tests, a few standard FUNDABAC® Filter models have been identified as a good fit for some of the most typical scrubbing capacities. These are summarised in the table below.

Smaller or larger Models are available too.

Please contact DrM for discussing in better detail about the possibilities of our filtration systems.

Selection Table of Standard FUNDABAC® Filter Models

Dry cake discharge of a FUNDABAC® pilot filter unit